Practice the Spirits of the 19th National Congress of CPC Enhance Risk-Prevention Awareness

2018-05-18

Post-loan on-site inspections on projects under operation in Hubei Province

Under the guidance of the principles of the 19th National Congress of CPC, China Clean Development Mechanism Fund (hereinafter referred to as “the CDM Fund”) Management Center actively carried out post-loan on-site inspection on supported projects by the CDM Fund (hereinafter referred to as “the CDM concessional loan”), with the aim to hold onto the bottom line of risks, reinforce monitor and regulation, and enhance the capacity of preventing and resolving financial risks.

From April 15th to 18th, the Management Center and Hubei Provincial Finance Bureau, carried out post-loan on-site inspection on three projects according to management procedures of projects. These projects are New Energy Automobile Purchase Project by Hubei Jinmen Public Transport Group Co., Ltd. (hereinafter referred to as “Jinmen Bus”), Annual Production of 2 Million High-Efficient Inverter Compressors Technological Transformation Project by Huangshi Donper Group Corporation (hereinafter referred to as “Huangshi Donper”), and Wuhai Natural Gas High Pressure Outer Circular Line Project by Wuhai City Natural Gas High Pressure Pipeline Net Co., Ltd. (hereinafter referred to as “Wuhan Natural Gas”).

The Management Center adopted ways of visiting the progress of on-site project construction, workshop with project owners and checking relevant information to carefully review the basic conditions of project owners, capital funded and utilization, project construction progress, financial status, operation condition and credit status of project enterprises and the security of funds supported by the CDM fund.

New energy automobiles refer to automobiles that utilize non-regular vehicle fuels to provide power and adopt new technology and structure with integration of advanced technologies of vehicle power control and driving system. The Jinmen Bus Project is about the input of high-efficient and energy-saving LNG buses into urban bus operation. Such a move can effectively reduce automobile exhaust and improve urban air quality. At the same time, adopting natural gas as power fuel can produce carbon-reduction benefit with low energy consumption.

The Project is basically under normal operation and the actual investment is as planned. The purchased clean energy buses with the brand of Xiamen Jinlv with a relatively high reputation in the industry. The Project adopted smart bus system, which provides functions of bus-locating, route-tracking and arrival forecast, and realized real-time dispatch, monitor and operation of buses, unified organization of intra-regional buses, and finally enhance strain capacity and service quality. Utilizing new energy buses to replace yellow-label diesel ones can effectively lower energy consumption and make transport more convenient for citizens, producing good social and environmental benefits.

The high-efficient and energy-saving inverter compressor is the core basic component of refrigerators. In order to meet the development demand for energy-saving refrigerators, the Huangshi Donper Project is about conducting a large-scaled transformation on existing products and newly building up a production line to produce transformed products, depending on its own advantages in technology and production. The new generation inverter compressor in Series L, which is mainly produced by this Project, can increase energy efficiency by 22% compared with the traditional freezer compressor under the same refrigeration effect. At the same time, the R600a refrigerant adopted by the new compressor won’t cause any damages to the ozone sphere as its ODP is 0, thus can produce much better environmental-protection effect.

The Huangshi Donper Project is under normal operation. Production factories are clean, tidy and standard, and production lines are clean and functioning smoothly. Smart “robot arms”, simple and high-efficient, were introduced into parts of the process to replace manpower. By supporting the promotion and application of the transformed products, the product can effectively reduce energy consumption of compressors, save power resource and promote low-carbon development. Meanwhile, by upgrading technological industry, it can increase resource utilization rate and local taxation, and boost the sustainable development of economy.

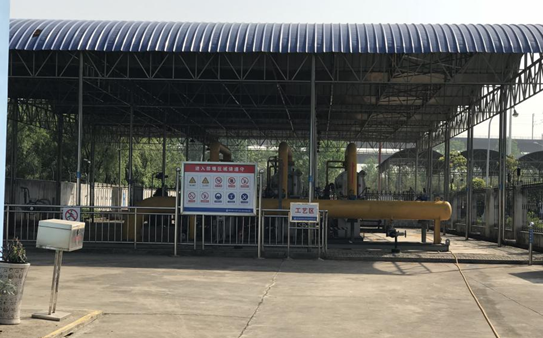

The main component of natural gas is methane, and it contains almost no sulfur, dust or other harmful substances. The amount of greenhouse gas produced during its combustion is significantly less than that produced by other fossil fuels. So natural gas is a clean, environmental-friendly and high-quality energy. The Wuhan Natural Gas Project adopts the advanced SCADA system (ie, data acquisition and monitoring and control system) to implement optimized operation management and monitoring on the entire pipeline. The system can predict the demand for natural gas, provide guidance for dispatch, and ensure the rational transmission and distribution and operation parameters of equipment, thus ensure effective energy utilization and energy savings.

The Wuhan Natural Gas Project is currently under normal operation. The gas station of the Project is managed in a standard way. Through real-time monitoring, the project is being operated safely and data is collected in time. Implementing this project can not only solve problems of natural gas short supply and weak peak load regulation capacity of Wuhan City, and facilitate the low-carbon development of local industrial enterprises, but also enhance gas emergency supply capacity and life quality of local people. Besides, the project has great significance to improving the energy mix of China, guaranteeing energy security and promoting energy-saving and carbon emission reduction.

Page Views : 212